Process Selection

Refers to deciding on the way production of goods or

services will be organized

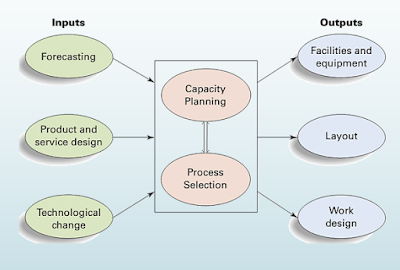

- Occurs as a matter of course when new products or services are being planned, also occurs periodically due to technological changes in products or equipment as well as competitive pressures.

- Has major implications for capacity planning, layout of facilities, equipment, & design of work systems.

Process selection & capacity planning influence

system design

Process Types

Five basic process types are

- Job shop

- Batch

- Repetitive

- Continuous

- Project

Product or Service & Flexibility Variety & Equipment Flexibility

Job Shop

- Customized goods or services

- Intermittent

- Operates on a relatively small scale

- High-variety goods or services

- Skill level of workers need to be high

Batch

- Moderate volume of goods or services

- Moderate variety

- Not much flexible but Intermittent

- Easy to add or change products or services

Repetitive/Mass

- Higher volumes of more standardized goods or services

- Slight flexibility of equipment

- Skill of workers is generally low

- Sometimes referred to as assembly

Continuous

- High volume of no discrete, highly standardized

- lmost no variety in output

- No need for equipment flexibility

- Skill requirements can range from low to high

Project

A no repetitive set of activities directed toward a unique

goal within a limited time frame

- Used for work that is no routine

- Unique set of objectives to be accomplished in a limited time frame

Such as consulting, making a motion picture, launching a new

product or service etc.

Process strategy

- The importance of flexibility as a competitive strategy is high

- However, flexibility does not always offer the best choice in processing decisions

- Flexible systems & equipment are often more expensive & not as efficient as less flexible alternatives

- In certain instances, flexibility is unnecessary because products are in mature stages, requiring few design changes, & there is a steady volume of output

Flexibility should be adopted with great care; its

applications should be matched with situations in which a need for flexibility

clearly exists.

No comments:

Post a Comment