This blog is created to share knowledge on modern manufacturing systems.

Showing posts with label Planning. Show all posts

Showing posts with label Planning. Show all posts

Thursday, September 28, 2017

Inventory planning & control, Types of inventory, Objectives of Inventory Control, Requirements for effective inventory management, Counting Systems,Inventory Costs, Economic order quantity (EOQ)

Inventory planning & control

A stock or store of goods

- The stored accumulation of material resources in a transformation system

- Allow the flexibility

- Exceptional quality

- Give a level of dependability

- Better return on investment (ROI)

Functions of Inventory

- To meet anticipated customer demand

- To smooth production requirements

- To protect against stock outs & take advantage of order cycles

- To hedge against price increases

- To permit operations

- To take advantage of quantity discounts

Enterprise resource planning (ERP), Implementation of ERP, Major Challenges to ERP Implementation

Enterprise resource planning (ERP)

Integration of financial, manufacturing & human resource

on a single computer system

- ERP software provides a system to capture & make data available in real time to decision makers & other users throughout an organization

- Provides a set of tools for planning & monitoring various business processes

Material requirements planning (MRP), Requirements of MRP, MRP input, MRP processing, MRP outputs, MRP II (Manufacturing Resources Planning)

Material requirements planning (MRP)

A computer-based information system that translate

requirements of MPS for end items into time-phased requirements for

subassemblies, components, & raw materials

- Working backward from the due date using lead times & other information to determine when & how much to order

Capacity planning & control, Steps in Capacity Planning, Measuring demand & capacity, Yield management

Capacity management

Capacity: The upper limit or ceiling on the load that

an operating unit can handle.

-The maximum level of value-added activity over a period of time that the process can achieve under normal operating conditions

- Capacity decisions have a real impact on the ability of the organization to meet future demands for products & services

- Capacity decisions affect operating costs

- Capacity is usually a major determinant of initial cost

- Capacity decisions often involve long-term commitment of resources

- Capacity decisions can affect competitiveness

- Capacity affects the ease of management

Planning & controlling capacity

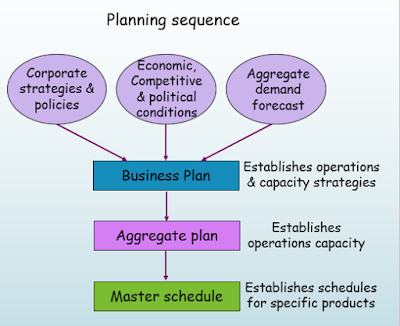

The nature of planning & control, Planning Horizon, Dependent and Independent demand, P:D ratio

The nature of planning & control

Planning & control is concerned with the reconciliation

between what the market requires & what the operation’s resources can

deliver

- Provide the systems, procedures & decisions which bring different aspects of supply & demand together

- Ensure that the operation’s processes run effectively & efficiently

- Produce products & services as required by customers

- Planning concerns what should happen in the future

- A statement of intention

- Control copes with changes

- An ‘intervention’ will need to be made in the operation to bring it back ‘on track’

Subscribe to:

Posts (Atom)