Aggregate planning

Intermediate-range capacity planning, usually covering 2 to

12 months

- A ‘big-picture’ approach to planning, focus on a group of similar products or services, or sometimes an entire product or service line

- Think of capacity in terms of labor hours or machine hours per period, or output rates

- Optimum utilization of plant

- Product grouping frees planners to make general decisions

- Flexibility to respond to the market

- Synchronize flow throughout the supply chain

Aggregate plans are updated periodically, often monthly, to

take into account updated forecasts & other changes

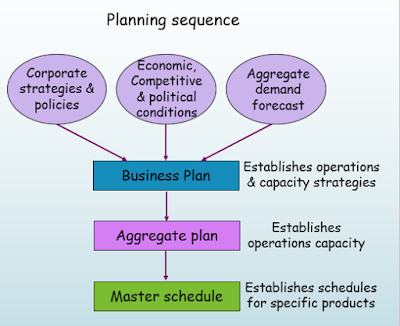

Inputs & Outputs of Aggregate Planning

Techniques for Aggregate Planning

A general procedure for aggregate planning consists of the

following steps

Use a worksheet or spreadsheet

- Determine demand & for each period

- Determine capacities (regular time, overtime, subcontracting) for each period

- Identify company or departmental policies that are relevant (maintain a safety stock of 5% of demand, maintain a reasonably stable workforce)

- Determine unit costs for regular time, overtime, subcontracting, holding inventories, back orders, layoffs & other relevant costs

- Develop alternative plans & compute cost for each

- If satisfactory plans emerge, select the one that best satisfies objectives. Otherwise, return to step 5

Use a worksheet or spreadsheet

No comments:

Post a Comment