This blog is created to share knowledge on modern manufacturing systems.

Thursday, September 28, 2017

Inventory planning & control, Types of inventory, Objectives of Inventory Control, Requirements for effective inventory management, Counting Systems,Inventory Costs, Economic order quantity (EOQ)

Inventory planning & control

A stock or store of goods

- The stored accumulation of material resources in a transformation system

- Allow the flexibility

- Exceptional quality

- Give a level of dependability

- Better return on investment (ROI)

Functions of Inventory

- To meet anticipated customer demand

- To smooth production requirements

- To protect against stock outs & take advantage of order cycles

- To hedge against price increases

- To permit operations

- To take advantage of quantity discounts

Enterprise resource planning (ERP), Implementation of ERP, Major Challenges to ERP Implementation

Enterprise resource planning (ERP)

Integration of financial, manufacturing & human resource

on a single computer system

- ERP software provides a system to capture & make data available in real time to decision makers & other users throughout an organization

- Provides a set of tools for planning & monitoring various business processes

Material requirements planning (MRP), Requirements of MRP, MRP input, MRP processing, MRP outputs, MRP II (Manufacturing Resources Planning)

Material requirements planning (MRP)

A computer-based information system that translate

requirements of MPS for end items into time-phased requirements for

subassemblies, components, & raw materials

- Working backward from the due date using lead times & other information to determine when & how much to order

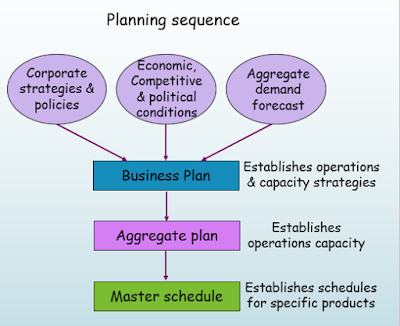

Capacity planning & control, Steps in Capacity Planning, Measuring demand & capacity, Yield management

Capacity management

Capacity: The upper limit or ceiling on the load that

an operating unit can handle.

-The maximum level of value-added activity over a period of time that the process can achieve under normal operating conditions

- Capacity decisions have a real impact on the ability of the organization to meet future demands for products & services

- Capacity decisions affect operating costs

- Capacity is usually a major determinant of initial cost

- Capacity decisions often involve long-term commitment of resources

- Capacity decisions can affect competitiveness

- Capacity affects the ease of management

Planning & controlling capacity

Subscribe to:

Posts (Atom)